About Burley, Idaho

Burley stands as the commercial heart of Cassia County, earning recognition as the “Hub City” due to its strategic position along major transportation routes connecting Utah, Nevada, and the Pacific Northwest. Founded in 1905 during the railroad expansion era, this vibrant community of approximately 11,000 residents has evolved into a regional agricultural and business center, anchored by industries ranging from food processing to manufacturing.

The city’s location in the Snake River Valley provides stunning views of the surrounding mountains while creating unique climate challenges that demand superior building performance. Burley experiences dramatic temperature swings, with summer highs reaching the 90s and winter lows plummeting below freezing, making effective insulation absolutely critical for year-round comfort and energy efficiency in both residential and commercial structures.

Transform Your Burley Property with Premium Spray Foam Insulation

Imagine walking into your Burley home during a harsh Idaho winter and feeling instant warmth without the shock of astronomical heating bills. Valley Spray Works delivers cutting-edge spray foam insulation solutions that revolutionize how buildings perform in Southern Idaho’s demanding climate, creating healthier indoor environments while dramatically reducing energy costs and carbon footprints.

Superior Insulation Solutions for Burley’s Unique Climate

Burley’s continental climate presents distinct challenges that standard insulation materials simply cannot address effectively. Temperature fluctuations of 60+ degrees between seasons create expansion and contraction cycles that compromise traditional insulation over time.

Our advanced spray foam technology forms a seamless thermal barrier that adapts to these conditions, maintaining consistent performance year after year. This superior approach eliminates the air leaks and thermal bridging that plague conventional insulation methods, ensuring your property remains comfortable regardless of external weather conditions.

Comprehensive Spray Foam Insulation Services

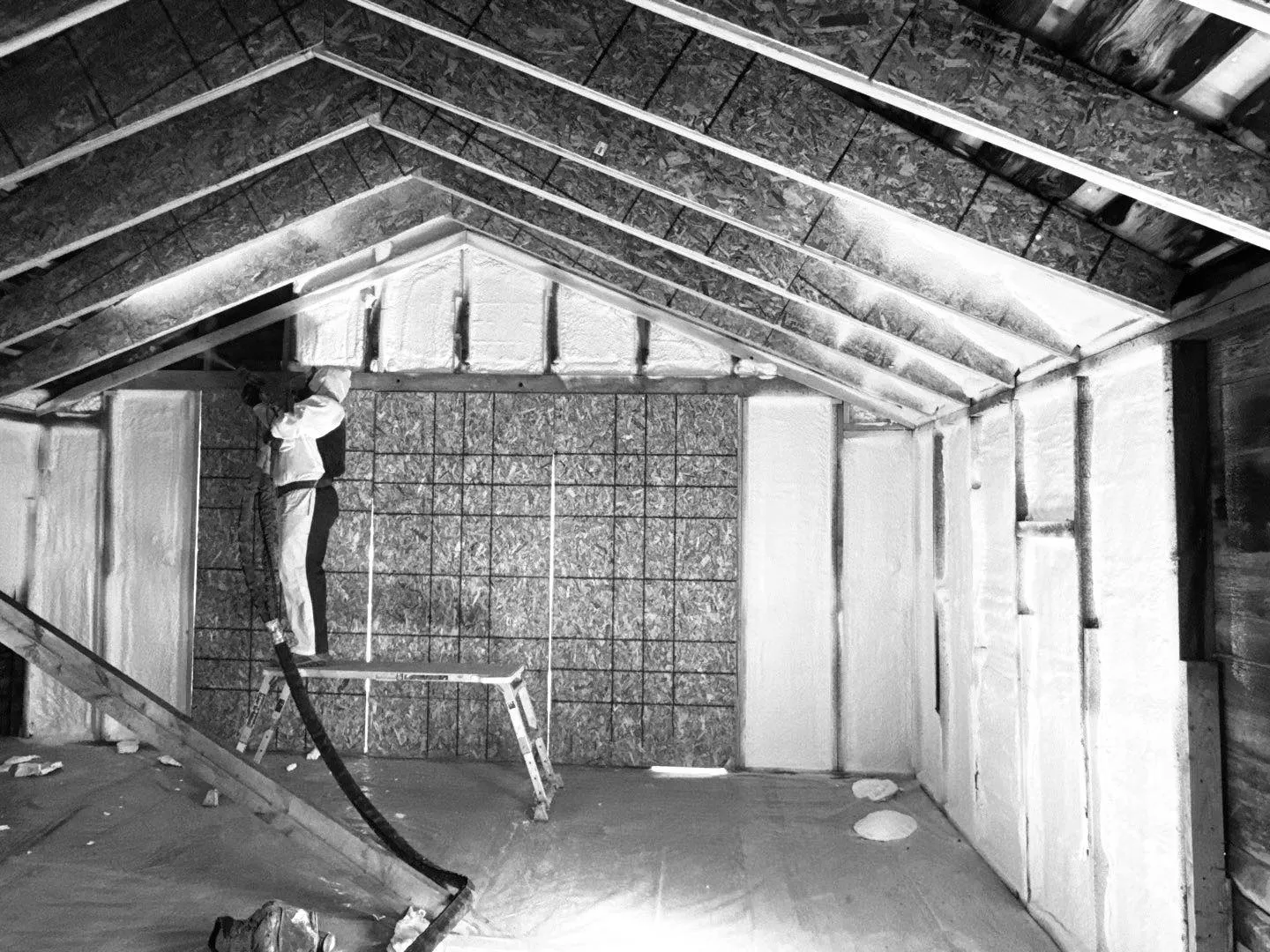

Valley Spray Works specializes in both open-cell spray foam and closed-cell spray foam applications, each engineered for specific performance requirements. Open-cell foam provides excellent sound dampening and flexibility, making it ideal for interior walls and attic spaces where moisture permeability is beneficial.

Closed-cell foam delivers maximum R-value per inch along with structural reinforcement and moisture resistance, perfect for exterior walls, basements, and crawl spaces. Our experienced technicians assess each project individually to recommend the optimal solution based on your building’s unique characteristics and performance goals

Professional Installation Process and Quality Assurance

Every spray foam installation begins with thorough preparation, including surface cleaning, masking, and climate control to ensure optimal application conditions. Our certified technicians use commercial-grade equipment that maintains precise temperature and pressure parameters throughout the spraying process.

Quality control measures include thickness verification, density testing, and visual inspections at each stage of installation. This meticulous approach guarantees proper adhesion, complete coverage, and long-term performance that meets or exceeds industry standards for thermal resistance and air sealing effectiveness.

Insulation Type | R-Value per Inch | Air Sealing | Moisture Resistance | Best Application |

Open-Cell Foam | R-3.7 | Excellent | Moderate | Interior walls, attics |

Closed-Cell Foam | R-6.5 | Superior | Excellent | Exterior walls, basements |

Blown-In Cellulose | R-3.6 | Poor | Low | Attic retrofits only |

Fiberglass Batts | R-3.2 | None | Poor | Budget applications |

Energy Efficiency and Cost Savings Benefits

Property owners who invest in professional spray foam insulation typically experience 30-50% reductions in heating and cooling costs within the first year. The Department of Energy reports that proper air sealing and insulation improvements can save homeowners an average of 15% on heating and cooling expenses annually.

Beyond immediate utility savings, spray foam insulation increases property values while improving indoor air quality by preventing drafts, dust infiltration, and moisture problems. These benefits compound over time, creating substantial long-term financial returns that far exceed the initial investment costs.

Things to Consider:

- Spray foam installation requires professional expertise and specialized equipment

- Temporary ventilation may be necessary during application and curing

- Investment costs are typically recovered within 3-5 years through energy savings

- Proper preparation ensures optimal performance and longevity

Get Trusted Insulation Services in Burley Today

Ready to transform your property’s energy performance and comfort levels? Valley Spray Works brings decades of combined experience and cutting-edge technology to every project in Burley and surrounding areas.

Contact us at (208) 539-5281 to schedule your comprehensive property assessment and receive a detailed proposal tailored to your specific insulation needs.

Frequently Asked Questions

How long does spray foam insulation last?

Professional spray foam insulation maintains its performance for 50+ years when properly installed, making it a long-term investment in your property’s efficiency.

Can spray foam insulation help with moisture problems?

Closed-cell spray foam creates an effective moisture barrier that prevents condensation and humidity issues common in basements and crawl spaces.

Is spray foam insulation safe for my family?

Once properly cured (typically 24 hours), spray foam insulation is completely safe and actually improves indoor air quality by sealing out pollutants and allergens.

How quickly will I see energy savings?

Most property owners notice immediate improvements in comfort and reduced energy bills within the first month after spray foam installation.

What’s the difference between open-cell and closed-cell foam?

Open-cell foam is lighter and more flexible with sound-dampening properties, while closed-cell foam provides higher R-value, structural strength, and moisture resistance.

Get Your Quote

Our Services

Locations We Serve

- Twin Falls

- Burley

- Rupert

- American Falls

- Hagerman

- Buhl

- Caldwell, ID

- Canyon County

- Cassia County

- Minidoka County